| Home |

| Research |

| Biochemical |

| Catalysis |

| Ceramics |

| DIPPR |

| Environmental |

| Minerals Processing |

| Polymer |

| Process Control |

| Process Design |

| Process Safety |

| Rheology |

| Thermodynamics |

PROCESS CONTROL

Faculty: Co, Kim

Advanced control systems are used by chemical industries to increase productivity, improve efficiency, and reduce waste. The implementation of advanced control needs to enhance reliability and safety, reduce variations in product quality, and expand flexibility in manufacturing to competitively meet changes in market demands.

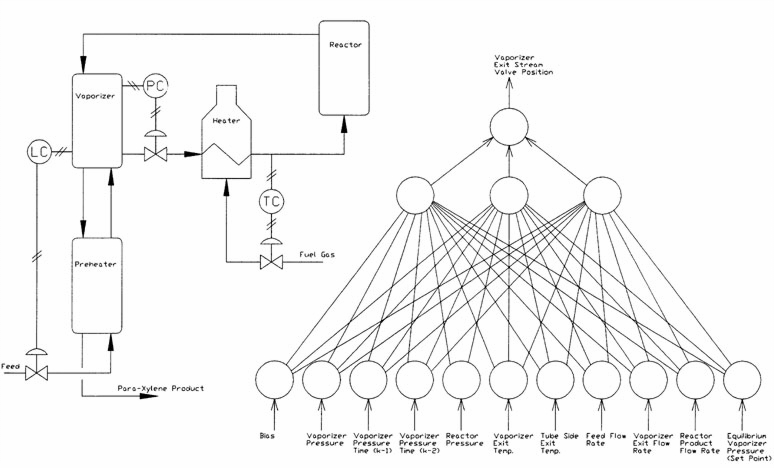

The focus of process-control research is to develop industrially relevant methods and tools. Current research areas include plant-wide distributed control, model-based predictive control, nonlinear control by neural networks and fuzzy logic control, and on-line process monitoring through advanced state and parameter estimation.

One of the unique facilities of the department is the Process Simulation and Control Center, which houses the Honeywell Total Plant System that is connected to several pilot-scale processing units. This laboratory allows the investigation of different distributed control strategies for pilot units, some of which are operated in batch mode. The facility also allows for development of real-time simulations to extensively probe different control strategies, start-up procedures, alarm handling and flowsheet/unit redesigns prior to real-world implementation. With the PSCC is the Control Laboratory, which houses smaller-scale units connected to PCs to allow faster and more extensive explorations of emerging techniques using artificial intelligence and advanced signal-processing tools.

Selected Equipment Process

- Simulation and Control Center facility including: Honeywell TPS distributed control system with Application module, universal stations (4), process manager and plant network module.

- DEC Alpha-based computers (2)

- OSI, Inc. PI software

- Hyprotech's HYSYS software

- MATLAB, MathCad, SIMNON, LabView, AspenPlus, ModelManager

Selected Theses/Dissertations

- Application of Neural Networks to an Industrial Rotary Calciner, PhD dissertation, A. Ciftci, in progress. Application of Neural Networks to Control of a Process with Recycle, MS thesis, T. Slawinski, 1996.

- Simulation and Control of a Chemical Plant to Minimize Waste during Warm Startup, MS thesis, U. Basu, 1995.

- Simulation and Control of an Industrial Rotary Calciner with a Heat Shield around the Combustion Zone, MS thesis, A. Ciftci, 1995.

- Experimental Studies of Pseudo-Fuzzy Logic Control in Non-Linear Processes, MS thesis, S. Hari, 1994.

- Control Studies of Strongly Interconnected Process Units, MS thesis, C. Buys, 1993.

- Simulation of an Industrial Rotary Kiln for the Purpose of Control System and Energy Conservation Studies, PhD dissertation, R. Srivastava, 1993.

- Microbial Coal Desulfurization: Simulation and Its Control Using a Programmable Controller, MS thesis, H. Eker, 1990.

- The Enzymatic Hydrolysis of Cellulose: Simulation and Its Control Using a Programmable Controller, MS thesis, R. Komm, 1988.

©

Copyright

2010,

All Rights Reserved Michigan

Technological University is an equal opportunity educational institution / equal opportunity

employer

|